Where and How to Safely Buy Sertraline Online: A Practical Guide

July 19 2025Manufacturing Quality: What Makes a Drug Safe and Reliable

When you take a pill, you trust it will work the way it should. That trust starts long before it reaches your medicine cabinet—in a factory where manufacturing quality, the set of controls and processes ensuring a drug is pure, consistent, and effective determines whether it saves lives or puts them at risk. It’s not just about the active ingredient. It’s about how it’s made, tested, packaged, and monitored. A poorly made tablet might break apart too fast, absorb unevenly, or contain hidden contaminants. That’s why pharmaceutical standards, the strict rules set by agencies like the FDA and EMA that govern how drugs are produced exist. These aren’t suggestions. They’re legally enforced requirements that separate reliable medicines from dangerous ones.

Many people assume all generics are the same. But that’s not true. Two drugs with the same active ingredient can behave differently if their bioequivalence, how closely a generic matches the brand-name drug in absorption and effect isn’t properly proven. Studies on drugs like warfarin and levothyroxine show that even small changes in how a generic is manufactured can cause dangerous fluctuations in blood levels. This isn’t theory—it’s documented in hospitals and clinics. And it’s not just about potency. Fillers, coatings, and even the color of a pill matter. Some patients react poorly to certain excipients because of allergies or cultural beliefs. That’s why drug safety, the ongoing monitoring of how a medication performs in real-world use isn’t just about clinical trials. It’s about tracking side effects, patient reports, and manufacturing changes over time.

Manufacturing quality affects everyone, whether you’re on a $200 brand-name drug or a $5 generic. It’s the reason some people feel worse after switching, why insurance companies fight over prior authorization, and why hospitals track dispensing errors back to the batch number. You don’t need to be a pharmacist to understand this: if the process is sloppy, the outcome is risky. The posts below dig into real cases where manufacturing flaws led to problems—from medication errors tied to confusing labeling to insurance denials because a generic didn’t meet expectations. You’ll see how cultural perceptions, scientific testing, and regulatory oversight all tie into whether your medicine is truly safe. This isn’t about fear. It’s about knowing what to ask, what to watch for, and how to protect yourself.

6 Dec

6 Dec

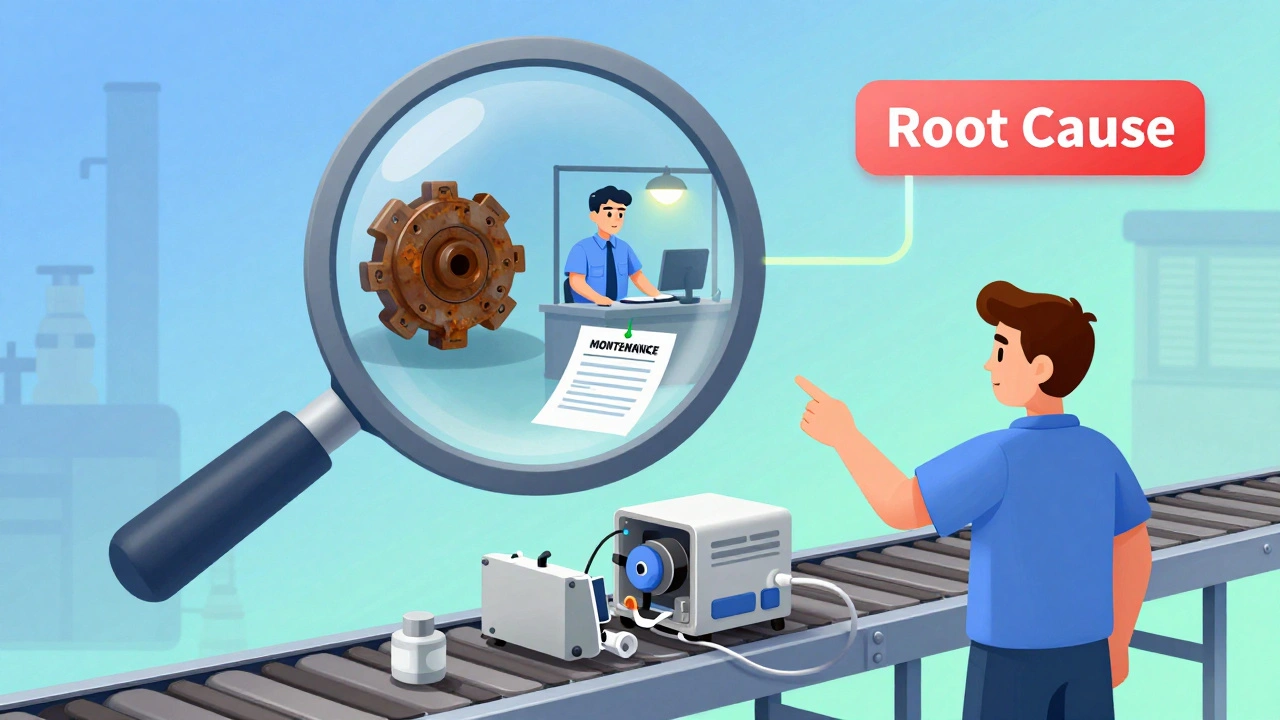

How Manufacturers Fix Quality Problems: A Practical Guide to Corrective Actions

Manufacturers fix quality problems through structured corrective actions that target root causes, not just symptoms. Learn how CAPA systems work, why most fail, and how to implement them effectively in regulated industries.

Read More... 27 Nov

27 Nov

Quality Assurance Concerns: Why Manufacturing Fears Are Reshaping Brand Trust in 2025

In 2025, quality assurance isn't just about meeting standards-it's the foundation of brand trust. Manufacturers ignoring quality risks losing customers, innovation, and market share. Here's how fear of failure is reshaping industry and consumer loyalty.

Read More...